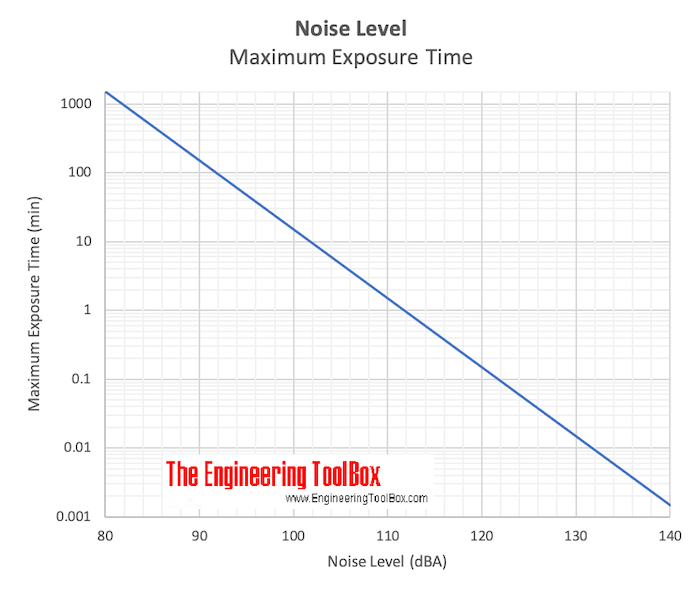

The third section describes worksite noise evaluations, including noise measurement equipment, noise evaluation procedures, and noise sampling procedures. Following this introduction, the second section provides background information about noise and noise regulations and an overview of available noise controls. The chapter is divided into seven main sections. The content is based on currently available research publications, OSHA standards, and consensus standards. This chapter provides technical information and guidance to help Compliance Safety and Health Officers (CSHOs) evaluate noise hazards in the workplace. Exposure to high levels of noise may cause hearing loss, create physical and psychological stress, reduce productivity, interfere with communication, and contribute to accidents and injuries. The Centers for Disease Control (CDC)/National Institute for Occupational Safety and Health (NIOSH) estimates that 22 million workers in the United States are exposed to hazardous noise. Hazardous noise is one of the most common occupational hazards in American workplaces. The mention of trade names, commercial products, or organizations does not imply endorsement by OSHA or the U.S. Associations, Education, and ConferencesĪppendix B – Sample Equations and CalculationsĪppendix D – Combined Exposure to Noise and Ototoxic SubstancesĪppendix E – Historical Analysis of Affected Industries and JobsĪppendix G – Evaluating Noise Exposure of Workers Wearing Sound-Generating HeadsetsĪppendix H – Economic Feasibility Analysis of Noise Engineering ControlsĪppendix J – Three Ways to Jump-Start a Noise-Control Program.Cost of Hearing Loss/Cost of Hearing Conservation Programs.Engineering Controls and Noise - Control Programs.Sound Levels of Equipment, Occupations, and Activities.Comprehensive Review - Noise, Hearing Loss, Noise Control.Engineering Controls and Economic Feasibility.Searching Online for Industry Noise Statistics.Noise Evaluation Instrument Care and Calibration.Personal Protective Equipment (Hearing Protection).Administrative and Work Practice Controls.Noise-Control Engineering - Concepts and Options.Brief History of Occupational Noise Standards.Ototoxicity and Synergistic Effects with Noise.Effects of Excessive Occupational Noise Exposure.Industrial Robots and Robot System SafetyĮxcavations: Hazard Recognition in Trenching and ShoringĬontrolling Lead Exposures in the Construction Industry: Engineering and Work Practice Controls Oil Well Derrick Stability: Guywire Anchor Systems Legionnaire's Disease, see OSHA's Safety and Health Topics Page for updated information.Ĭontrolling Exposure to Hazardous Drugs, see OSHA's Safety and Health Topics Page for updated information. Polymer Matrix Materials: Advanced Composites The chart below shows different types of power tools and their noise levels.Technical Equipment: On-site Measurements Duration is typically measured over a workday and accumulated through many years. The noise level is therefore expressed in decibels (dB) on the "A" scale, or dB(A).ĭuration of exposure is equally important.

Most workplace noises include a wide band of frequencies and are measured through the "A" filter in sound-level meters. Sounds must also be specified in terms of frequency or pitch. Hearing protection should be used for any level over 85 dB and double protection for any level over 105 dB. In other words, sound intensity doubles every 3 dB.

But 93 dB is still twice as much noise as 90 dB. A sound 1,000 times more powerful than near total silence is 30 dB.įor example, a backhoe and a compressor each producing 90 dB have a combined output of 93 dB, not 180. A sound 100 times more powerful than near total silence is 20 dB.

On the decibel scale, the smallest audible sound (near total silence) is 0 dB. This means that noise levels can't be added directly like other numbers. The decibel scale is not linear but logarithmic. Decibel (dB) is the unit used to measure a sound's strength.

0 kommentar(er)

0 kommentar(er)